Active Fan Control

Plant ControlCEREBRO HumanDroid 4.0 ™

A new era in the integration of processes between man and machine is finally available. At the gates of the fourth industrial revolution a computer brain is born, available to increase the degree of safety and reliability of suction systemsCEREBRO HumanDroid 4.0 ™ has always-on control functions in Predictive and Reactive mode, in order to safeguard the integrity and productivity of the suction systems. Many processes are linked to the correct operation of the suction system: robots, laser cutting, recovery of potentially harmful or explosive fluids, just to mention a few examples. CEREBRO™ controls the ventilator health status and all its main components by continuously monitoring, 24/7, every trend in search of even the smallest non-compliant detail. Its predictive capacity analyzes every second the point of operation during atmospheric emissions from tribo probes, or the state of clogging of filtering systems. Reactive systems intervene instantaneously in order to avert dangers arising from the exceeding of a threshold or the blocking of an electrical organ under its control. CEREBRO™ has an extremely advanced computer brain that allows a first immediate action executing entire safety chains in just a few moments; like a skilled android at the same time it warns its operator of what has happened and positions itself in standby mode ready to receive subsequent orders. All sensitive data are available at a glance: voltages, powers, absorbed currents, frequency, operating sequences.

The systems of automatic adjustment speed can be based on variations in pressure, temperature, the presence of CO2, pollutant dust, or change autonomously according to unpredictable external changing conditions (thunderstorms and gusts of wind, for example). Its sensors can modify pressure differences with hysteresis of up to 1 mm, temperature variations with a degree +- 0.1 °C making it flexible to needs with a wide choice of probes to be inserted on request.

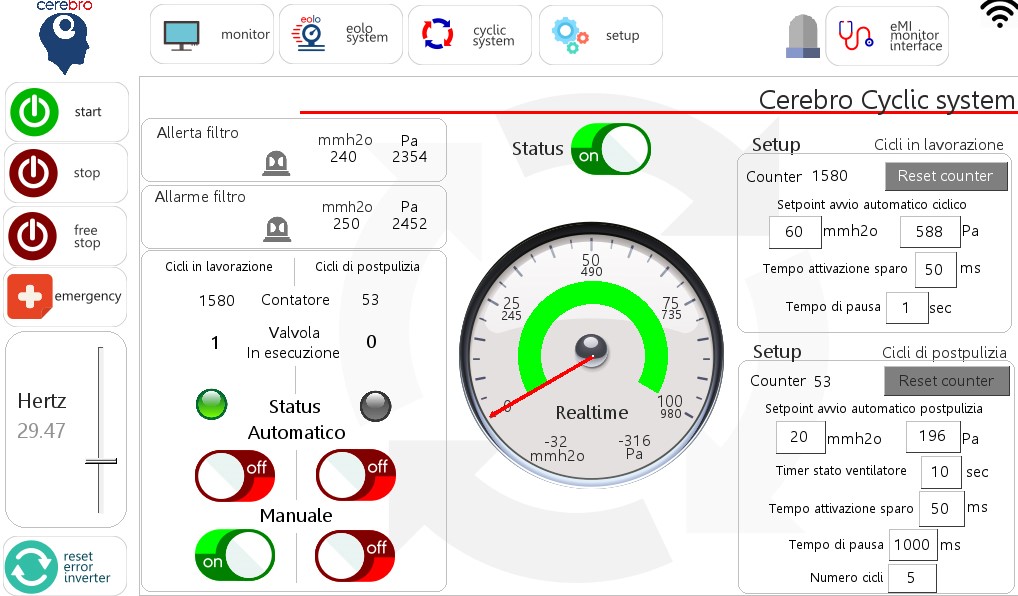

A cyclic system that can be described as worthy of a world that is now digital. The CEREBRO Cyclic System ™ moves away from everything that is on the market today, with the desire to help mend the rift that has been created at a technological level in the industrial field of vacuum systems. The information technology that has invaded our world with the latest generation of smartphones too often does not interact with our daily tasks in the workplace, does not help us to optimise processes, forcing us to run from one department to another in search of the fault, of the buzzer that will unequivocally lead us sooner or later to find a luminous column with a red light on it. CEREBRO™ definitively solves this problem with a user interface within the reach of every operator, always active and compliant with all operating systems and latest-generation hardware, ready to work with LAN or 3G/4G connection. Thanks to this technology it will be possible to check the health status of the filters at any time, change the firing latency times, switch from automatic to manual mode or check the pause times for post-cleaning. Even from the comfort of your own computer.

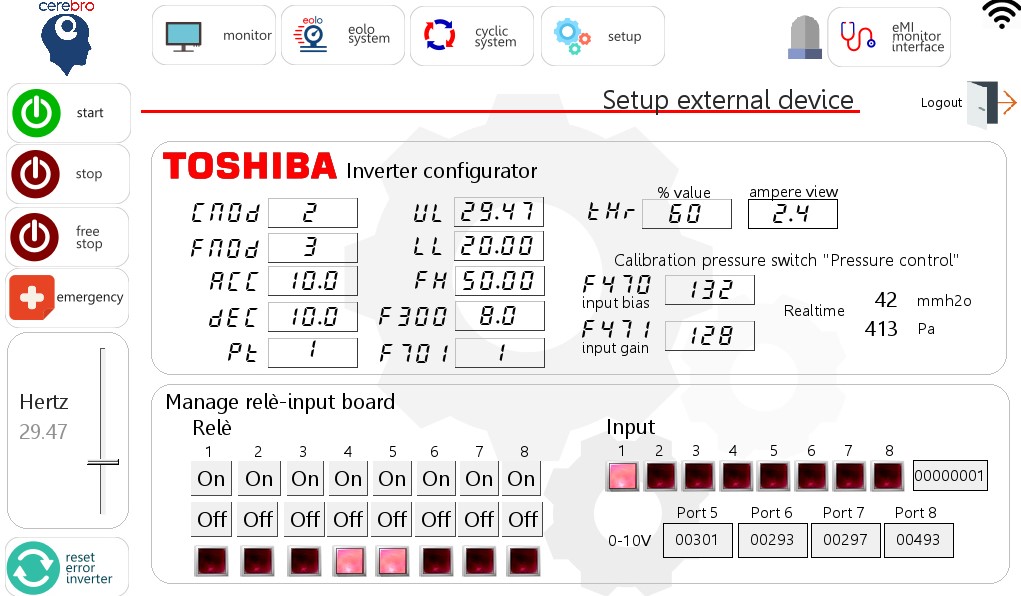

Its SSL encrypted protections and the support site in crash recovery without direct bridge with the end user guarantee the usability of the product and the highest possible security, making it an irreplaceable companion in the working day of all those operators responsible for the safety and functionality of the process systems, for many companies of even radically different sizes and characteristics. Changing the parameters of a frequency converter without having to open the door of the panel with the risk of working under voltage? Today you can do it. CEREBRO™ offers among its features several options in setup, including the modification of parameters from the outside, and especially remotely for the frequency converter, for the operator panels and numerous external devices with variable function depending on user needs. How could the trusted doctor be missing in a system so attentive to the health of the plant? eMI ™, the Eolo Monitor Interface, gives us

Safety and Reliability

Your protections SSL encrypted and the support site in crash recovery without direct bridge with the end user, they guarantee the usability of the product and the maximum possible safety, making them an irreplaceable companion in the working day of all those operators responsible for the safety and functionality of process systems, for many companies of even radically different sizes and characteristics.

Changing the parameters of a frequency converter without having to open the door of the panel with the risk of working under voltage? Today it can be done. CEREBRO™ offers among its features several options in setup, including the modification of parameters from the outside, and especially remotely for the frequency converter, for the operator panels and numerous external devices with variable function according to user needs.

How could the doctor be missing in a system that is so attentive to the health of the implant? eMI ™, theEolo Monitor InterfaceIt will instantly update us on what is happening out of the ordinary with an instant decoding of the drive's error message. All elements under its control will be viewable and any abnormal intervention, from thermal trip to exceeding the warning threshold for filter pressure, will be displayed. notified immediately.

Functionality of CEREBRO™ Systems

It allows you to define an acceleration scale that does not depend only on what is set in the drive, but can be defined directly by the system operator, the only one who really knows how to make his machines work at their best.

Dedicated to the management of variable speed with constant pressure or temperature.

is our ABS that prevents the threshold of the setpoint from being exceeded in order to avoid dangerous fluctuations of the fan and thus safeguarding the integrity of the electric motor.

The system is a sub-process of the Eolo System ™ and Vulcano System ™ that intervenes automatically in order to control an overflow of the suction system in the event of a malfunction of the same, for example, due to counter-flows to the pressure switch generated by suction arms on a system with instability problems. In this case the hysteresis, the StepHerz ™, the constants KP,KD,KI and above all the C Factor ™ are normally sufficient to allow the operator to stabilize the system, but with a continuous logical thread linked to the optimization of the system itself in absence of a human operator, and therefore automatically, Guardian ™ reading the parameters in real time will intervene in case they should malfunction for more than 3 minutes. In this way it will stabilize the plant generating a consequent e-mail to the operator that will warn him of the emergency intervention occurred.

A measurement wing guarantees the actual flow rate in the system and, when implemented, it is possible to check the operation of the fan in real time by entering its curve on a dedicated page. The Direct and Sensitive systems of Vulcano System ™ are able to harmonise the air flow rate with the temperature variations also in a sensitive way for the internal stability of the microclimate. Fire-fighting management with system blockage and filter flooding when the threshold defined by the thermo-velocimeter is exceeded. The CERBRO™ systems are many and varied, but all have a single objective. In today's modern industrial plants, safety is the priority for any company and providing operators with the right tools to be able to maintain these high standards is a must. Being able to trust your production systems, creating an anthropomorphisation of what until yesterday seemed to be just a collection of cables and circuits, is the reason why CEREBRO™ was born.

CEREBRO™, a "HumanDroid Brain" at your service 365 days a year.