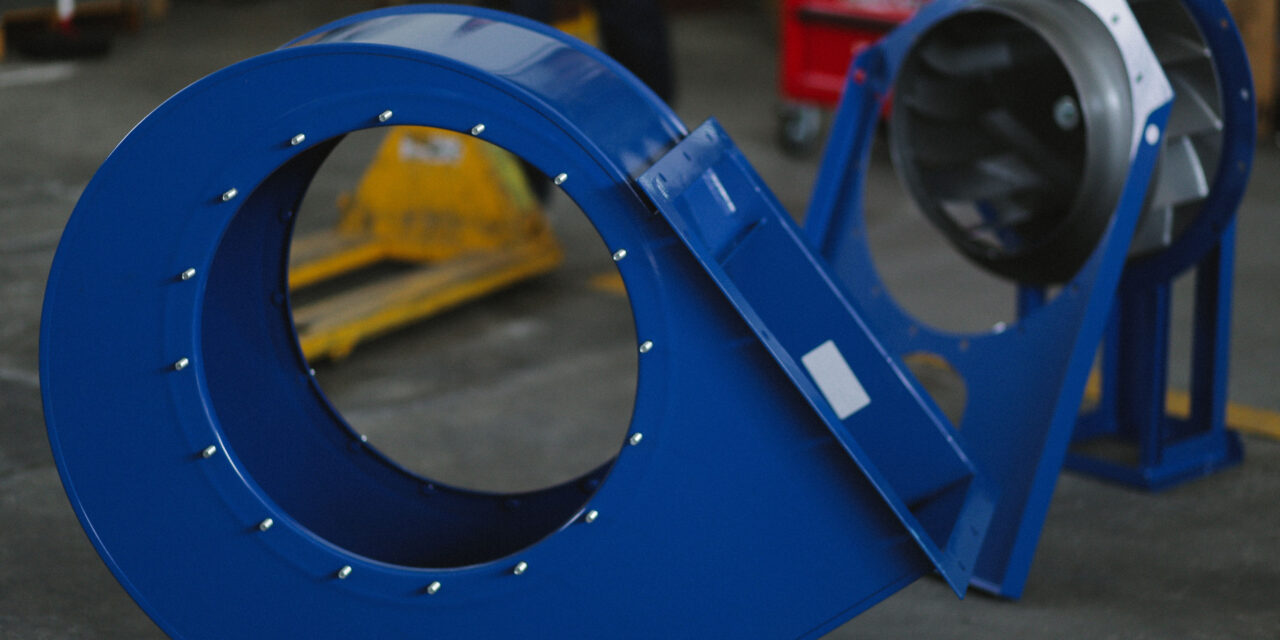

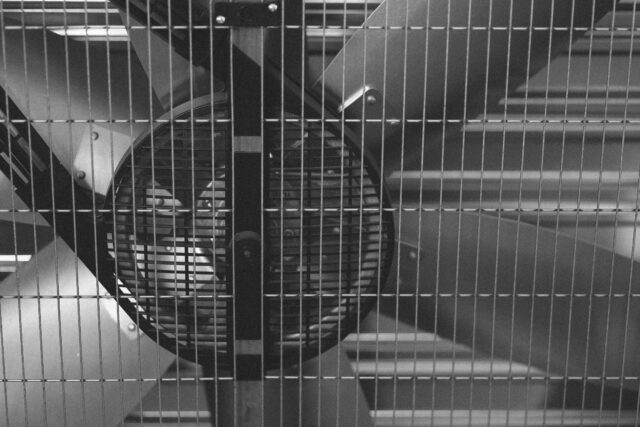

Industrial production plants produce a lot of hot air during daily production processes. Whether it's a metal forge, a paper press, a glass furnace or a compressor room, there is plenty of hot air. Fortunately, industrial fans are suitable for expelling hot air and improving the condition of the building.

Here are the main advantages of investing in industrial ventilation: industrial ventilation:

LOWER TEMPERATURES

Industrial ventilation equipment, such as fans and wall grilles, improves the building's airflow. Using the principles of natural ventilation, a vent on the roof expels suffocating air and the wall vent injects fresh air. This increase in air exchange makes the structure cooler and more comfortable. The right industrial ventilation system allows temperatures to be lowered by 1°C or more.

- REGULATION AND CONTROL

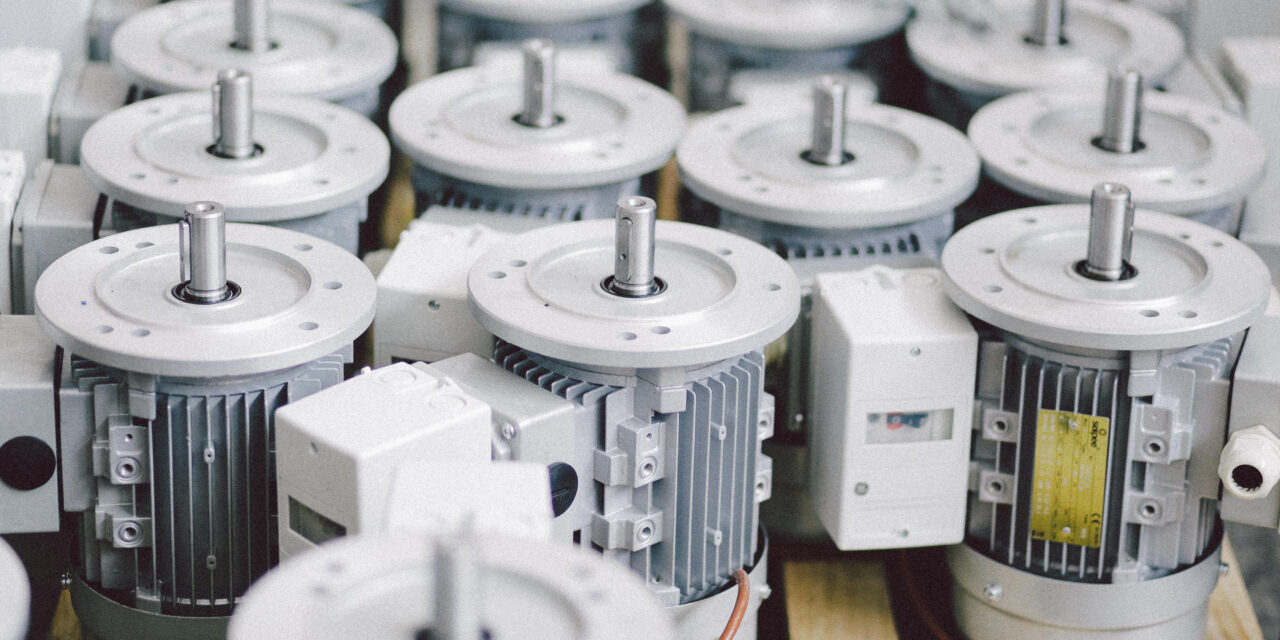

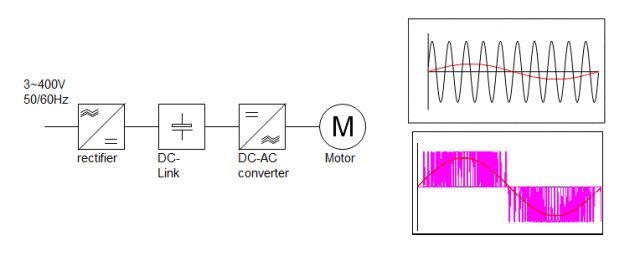

One of the key advantages of installing industrial fans is the ability to control the entire airflow inside the facility. Whether it's a simple control switch or fully automated controls, an intelligent solution allows precise air control, allowing you to adapt to production variations, internal temperatures and external factors, creating a comfortable working environment.

INDUSTRIAL VENTILATION SAFETY

High temperatures can create a number of problems. From dehydration to equipment deterioration, the risks are numerous. Lower temperatures help protect workers and mitigate indoor pollution levels.

NEGATIVE EFFECTS OF POOR VENTILATION

The likelihood of an immediate reaction to poor air quality depends on several factors, such as age and the possible presence of existing diseases.

Some effects may only occur in the years following prolonged exposure to poor ventilation, including respiratory disease, heart disease, and cancer. In some cases, these problems can be fatal.

However, it can be difficult to pinpoint a specific concentration or period of exposure that may produce health problems due to poor ventilation, while the likelihood of significant long-term health effects varies from person to person.

For these and other reasons, proper ventilation is essential to ensure worker safety.

Contact us, one of our consultants will be ready to help you find the most effective ventilation solution for your company, click here.