Industrial fans, in substantial terms, have taken on an almost capital importance in everyday life. In the hottest seasons, the heat increases considerably every year and tools of this kind are essential resources in all respects for the well-being of workers and

of the company itself. From a technical point of view they stand out for their technical characteristics and design conformity. Here, then, is an overview about it.

How a fan is made and when it is suitable by law

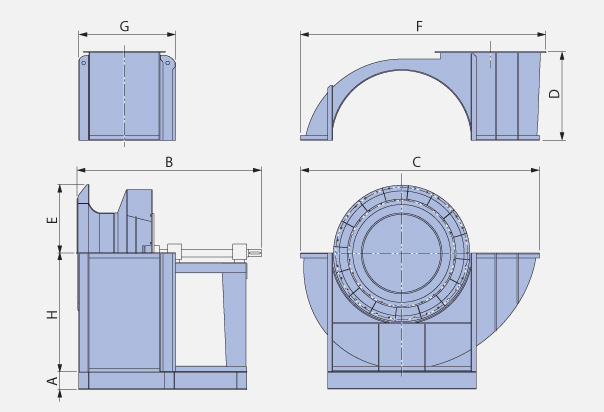

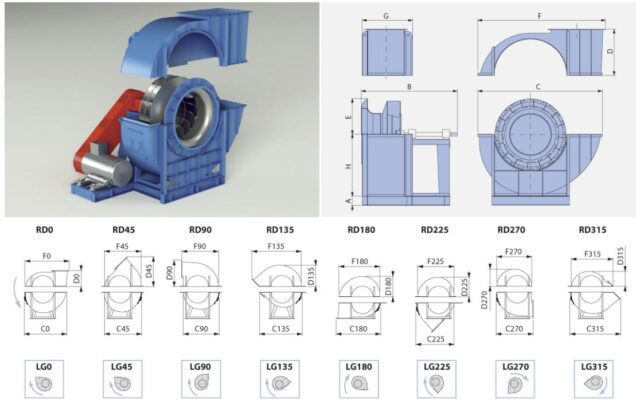

Industrial fans, whatever they are axial or centrifugal, as well as all electronic products, must comply with precise European regulations in order to be considered safe and suitable to be placed on the market. The rule that regulates, in this sense, the installation and extraction methods is called UNI ISO 13349. What makes a fan perfectly suitable from a practical perspective is the type of installation towards which it can tend. There are exactly four on a functional level: free suction and delivery, free suction with pipe delivery, pipe suction and free delivery, pipe suction and delivery. The function of the guards to be considered becomes fundamental when using type A installation. It allows essential elements such as suction and delivery to be kept away from accidental impacts and pressures. Type B includes guards on both the suction and delivery fronts.

Scale fixing which is also common to type C assembly (with pipe suction). Only type D is characterized by the total absence of guards positioned on the fan's delivery and intake. At this point the assembly, valid for all types of ventilation, makes use of an anti-vibration joint capable of providing greater stability to the instrument, avoiding wear and structural vibrations.

In order for legal suitability to also be guaranteed in terms of safety, a series of conditions must be respected against anomalies and improper manoeuvres. For example, never remove safety devices or shelters yourself unless expressly specified in the instruction manuals. The use of the fan in circumstances and contexts other than those indicated in the compliance directives is prohibited. Just as it is not advisable in the slightest, if not strictly prohibited, to act independently on defects and malfunctions that may compromise its stability.

Better to follow a very precise and sequential process from a procedural point of view. In the event that an operator has the necessary skills to be able to act in this sense, he must, at the same time, possess personal protective equipment. Small precautions, but they can save lives on both fronts.

Fans for potentially explosive environments

The fans produced by MZ Aspiratori, of which we are resellers, comply with the 94/9/EC directive and designed according to the EN14986 standard which indicates fans intended for potentially explosive atmospheres.

The Atex certified fans have been designed and built for use in areas classified as 1/21 and 2/22 and are suitable for conveying flammable and combustible substances, in compliance with the indications of the ATEX Directive 2014/34/EU. There ATEX directive and CE marking require compliance with the machinery directive, for which the Atex fan, at a regulatory level, must be considered as a partly completed machine and therefore completely protected, since it is integrated into more complex systems. Even if the safety of the systems is guaranteed, the protections must still be left with the fan and also in anticipation of a possible change of intended use of the same.

Tutti i ventilatori standard MZ Aspiratori conformi alla direttiva ATEX, sono stati esaminati dalla commissione del TÜV NORD ed hanno ricevuto la relativa certificazione.

In Meridiana Aspiratori siamo da sempre impegnati a soddisfare le esigenze del cliente, assicurando i più elevati standard di qualità e sicurezza. L’obiettivo della nostra azienda è integrarsi con i processi produttivi e le dinamiche aziendali di chi chiede i nostri prodotti e i nostri servizi, offrendo una qualità migliore e diversa anche sotto il profilo umano. Per adempiere a questa missione, abbiamo una struttura organizzativa articolata, altamente specializzata, a supporto delle aree tecniche, gestionali e operative delle aziende che operano in vari settori merceologici. Un processo complesso che pone al centro la salute dei lavoratori, la tutela dell’ambiente e la centralità del rapporto con i nostri Clienti, motivi fondamentali per realizzare un vantaggio competitivo stabile e duraturo.