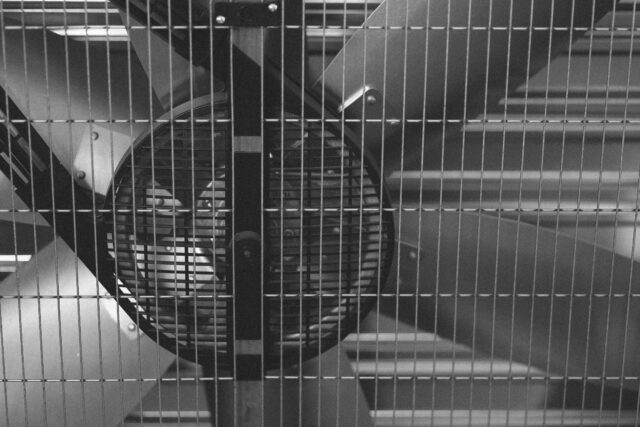

Industrial centrifugal fans are devices used to move large volumes of air or gas in industrial environments. They are called "centrifugal" because they use centrifugal force to move air or gas through the ventilation system. These fans consist of a blade rotor that rotates inside a cylindrical housing, called a "casing."

Air or gas enters the casing through an inlet nozzle located on the side of the device, then is accelerated towards the rotor, where centrifugal force pushes it outward towards the top of the casing, where it is expelled through an outlet nozzle located on the top of the device.

These fans are used in a wide range of industrial applications, including ventilation of production areas, air cleaning in purification plants, and air conditioning of workspaces. They can be designed in various shapes and sizes to fit specific application needs.

The use of industrial centrifugal fans depends on the specific requirements of the application. However, in general, they are used to move large volumes of air or gas in industrial environments.

Here are some examples of how they can be used:

- Ventilation: centrifugal fans can be used to extract stale air or fumes produced during the production process and replace it with fresh air from outside. This improves the air quality inside the workspace, creating healthier and safer conditions for operators.

- Air cleaning: these fans can be used in air purification plants to remove impurities or contaminants present in the air, such as dust, smoke, harmful gases, and odors.

- Air conditioning of workspaces: centrifugal fans can be used to cool or heat the air inside the workspace, improving the thermal comfort of operators and increasing the efficiency of the production process.

- Smoke extraction: centrifugal fans can be used to extract fumes produced during the welding process, reducing the exposure of operators to harmful substances and improving the air quality inside the workspace.

Vapor and gas extraction: these fans can be used to extract vapors or gases produced during the processing of chemicals, improving the safety of operators and the workspace environment. In any case, the use of industrial centrifugal fans must be supported by adequate design and installation of the ventilation system to ensure maximum performance and energy efficiency.

Our products

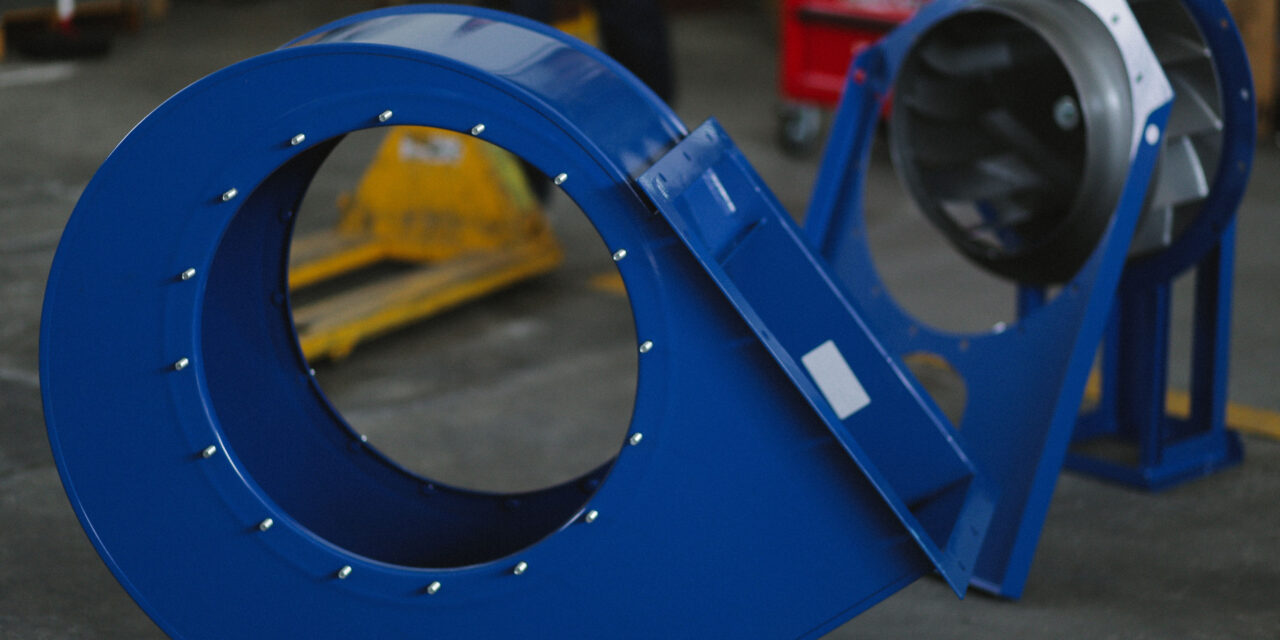

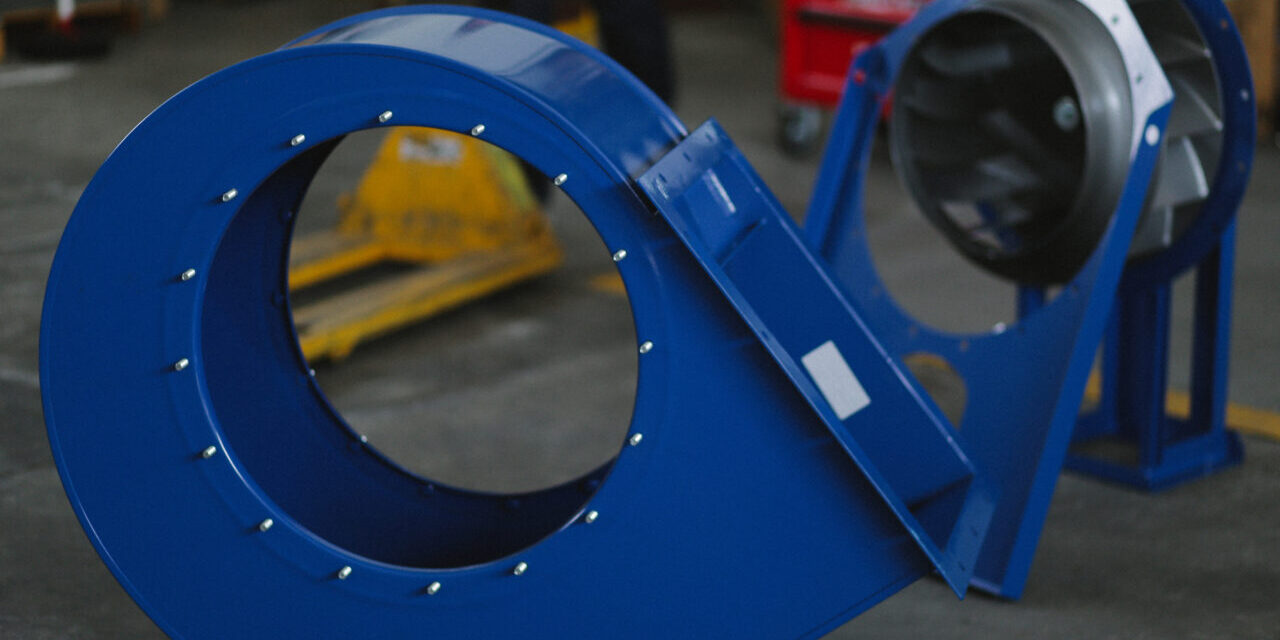

Our company offers a wide range of these products. Here are some examples:

- CA SERIES and SR SERIES, SRQL, RLD - RL: Suction and transport of clean or slightly dusty air for various applications in industrial plants and air conditioning.

- CB SERIES: For the suction of clean air, vapors, where large volumes of air are moved with low pressures.

- GF SERIES: Suction and transport of clean or dusty air, even containing low quantities of sawdust, various chips, granular materials, except filamentous materials.

- GR - RH SERIES: Suction and transport of clean or slightly dusty air. Suitable for the transport of solid materials mixed with air, chips, and sawdust with a fan not crossed by the material.

- VC/N- VG/N - VI/N - VH/N SERIES: Suction and transport of clean air. With a fan not crossed for pneumatic transport, drying, pressurization, cooling.

- P, SA, SC Series: For exhaust gas aspirators, used in the automatic machinery industry, plastics industry, and granulators.

- ZA – ZB SERIES Suction and transport of very dusty air with suspended material also containing sawdust, various shavings, granular materials. ● ZC-ZD-ZM SERIES Suction and transport of very dusty air, with material in suspension, also containing sawdust, various shavings, granular materials, filamentary materials

- SERIE ZC-ZD-ZM Aspirazione e trasporto di aria molto polverosa, con materiale in sospensione, anche contenente segatura, trucioli vari, materiali granulari, materiali filamentosi.

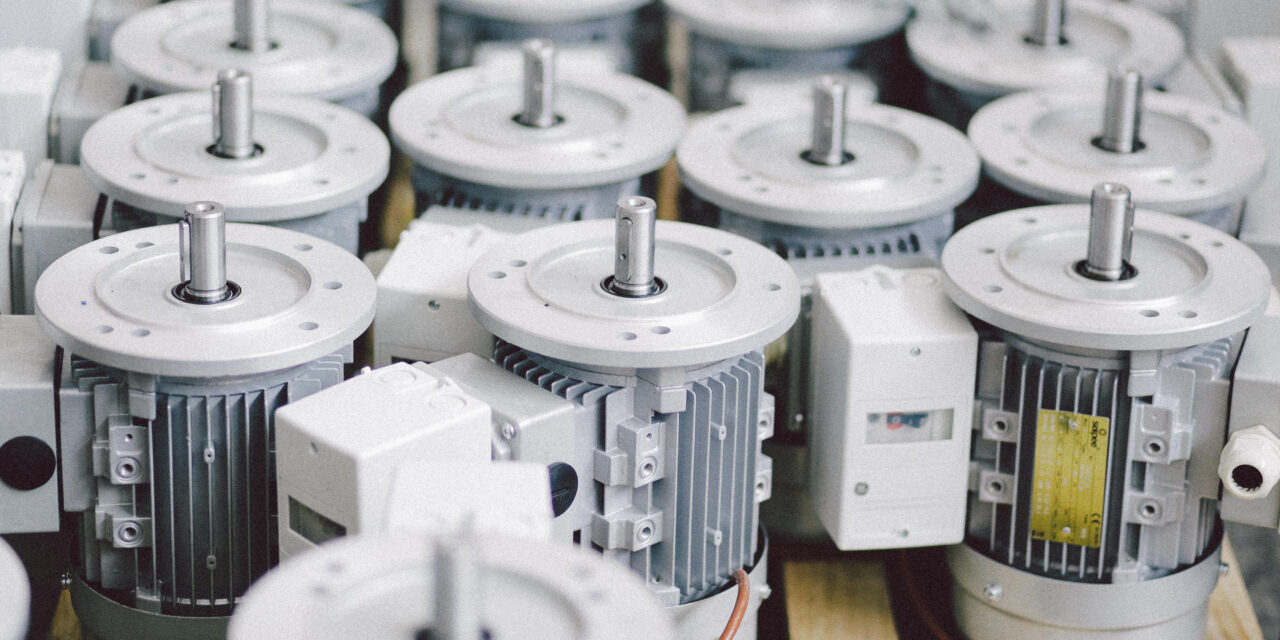

Meridiana Aspiratori has acquired over time technical and executive skills, whose competitive advantage lies in playing the role, not only of a supplier of high-quality products but also of unique services, such as consulting and engineering of industrial ventilation and suction systems, designed and processed based on the real needs of each individual customer.