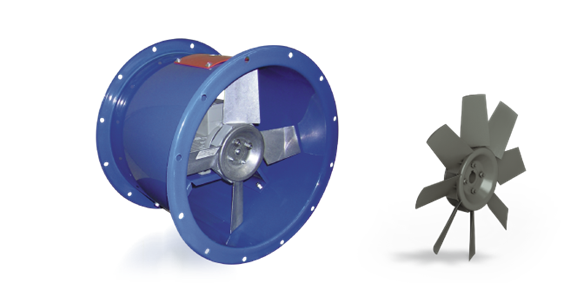

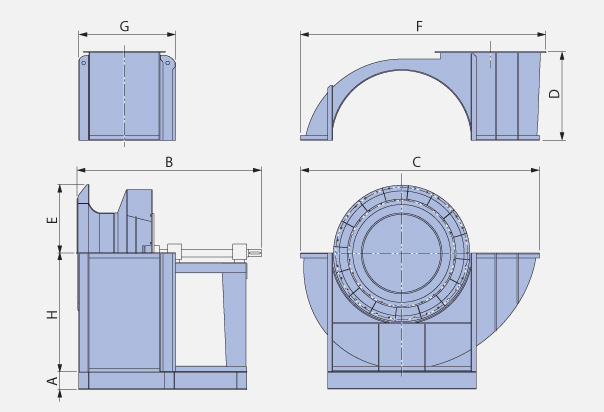

Centrifugal fans are a pivotal component in various industrial and commercial applications such as ventilation, heating and cooling systems, and material handling. In the rapidly expanding domain of air-moving equipment, the quality and efficiency in which an air-flow system operates play a vital role in daily life. When it comes to centrifugal fans, the key component to maximize efficiency is by selecting suitable centrifugal fan accessories.This article will expand on the importance and impact of having the most relevant accessories equipped for your centrifugal fan systems.

Types and functions of important centrifugal fan accessories

To ensure the system runs at optimum levels, safety, efficiency, and maintenance are the three primary aspects to focus on. Consequently, the centrifugal fan-related accessories are generally sorted into three categories. Let's dive into each category and outline the significance of the fundamental components

- Add-on Components for System Safety

Safety is of utmost paramount regardless of the specific application a centrifugal fan is performing. Thus, the range of safety-related accessories are essential to enhance the overall security without affecting daily tasks revolving around the work environment. Here are the main safety-centric accessories.

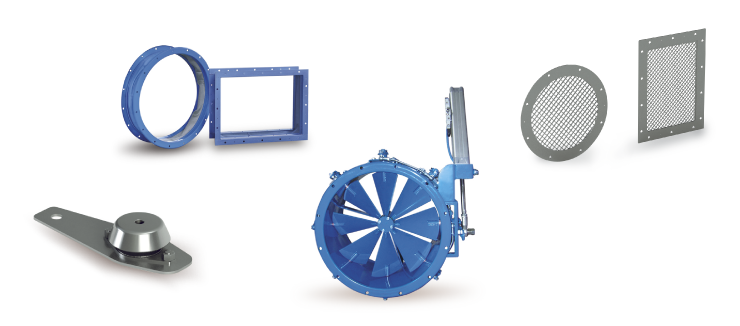

Protections uards - Commonly used fan guards and inlet/outlet guards shield the fan's rotating components, protecting users and assets from accidental contact.

Guards - Commonly used fan guards and inlet/outlet guards shield the fan's rotating components, protecting users and assets from accidental contact.

Vibration Isolators - Help in reducing the transmission of vibrations to adjoined surfaces or objects, which not only deplete overall noise levels but also maintain the integrity of fan components over time.

Motor Support Bases - These accessories support the fan motor, ensuring its proper alignment and optimum output potential without any compatibility is interfered by erroneous mounting or movement

Motor Support Bases - These accessories support the fan motor, ensuring its proper alignment and optimum output potential without any compatibility is interfered by erroneous mounting or movement.

- Controlling and Improving Efficiency

Numerous accessories are available to enhance and refine fan performance without compromising fan reliability or longevity. Such accessories depend primarily on the application type and customer requirements – yet, they are crucial parameters for maintaining overall system effectiveness. Some essential efficiency-centered enhancements to centrifugal fans include

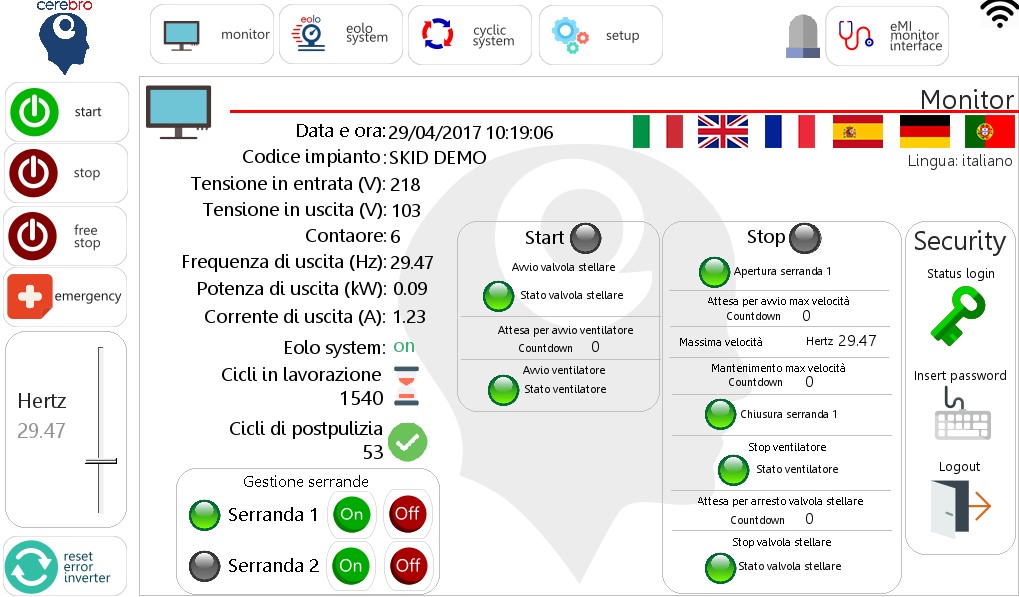

Speed Controllers Fan's performance can be further fine-tuned, enabling the fan's and energy consumption rates to flexibly adapt as needed basis using speed controls or variable frequency drive (VFD), which is especially crucial in energy-intensive or constantly shifting industrial

DampersHelps to moderate the airflow rate and air pressure by enlarging or narrowing the fan outlet proportionally. They are beneficial for applications that have fluctuating demands, allowing frequent control of the air stream without disturbing the fan speed.

- Necessary maintenance and spare components

Like all other specialized industrial equipment, the centrifugal fan apparatus need regular checks and preservation through general replacement of components to guarantee optimum service life over time. Such elements, like regular centrifugal fan maintenance, are mandated by health and safety requirements, enhancing general performance stability indefinitely. Some of the valuable components deemed necessary are: filter component and bearings

Filter component

Replacement fan filters ensure a continuous flow of clean air and also limit the germs, pollutants, and particles that lead to wear on internal parts.

Bearing

Since centrifugal fans can operate continuously for a prolonged duration, the bearings get subject to wear and tear. It is important to be aware of fan's lubrication intervals and know when it's replaced

In conclusion, selecting appropriate centrifugal fan accessories contributes immensely to enhancing performance efficiency, offering a safer environment, and delivering platform security over time. Decisive selections based on application necessities ensure smooth mechanics within manifold facets, adhering to industrial standards.

We at Meridiana Aspiratori operate with a multidisciplinary approach that puts our customer at the centre, starting with an in-depth analysis of his specific needs, from the organizational context and arriving at the identification of the most suitable and safest solution for optimal achievement of the final result.