Electric motors are a fundamental component in industrial exhaust and ventilation systems, playing a crucial role in ensuring efficiency, safety, and sustainability across various production environments. These systems are essential for maintaining a healthy working environment, controlling pollutant emissions, and ensuring the proper operation of machinery and industrial processes.

- Energy Efficiency

Modern electric motors are designed to offer high energy efficiency, reducing consumption and operational costs. In exhaust and ventilation systems, where motors often operate for long periods, the use of high-efficiency motors allows for significant energy savings compared to traditional models. This not only has a positive economic impact on companies but also contributes to reducing CO₂ emissions, aligning with environmental sustainability goals.

- Reliability and Durability

Electric motors used in industrial applications are built to withstand demanding operating conditions, such as high temperatures, humidity, and exposure to dust and chemicals. Their reliability is essential for ensuring the continuous operation of exhaust and ventilation systems, preventing costly and potentially dangerous machine downtimes. Moreover, the maintenance of these motors is generally less complex than that of other technologies, contributing to a longer operational lifespan.

- Emission Control and Air Quality

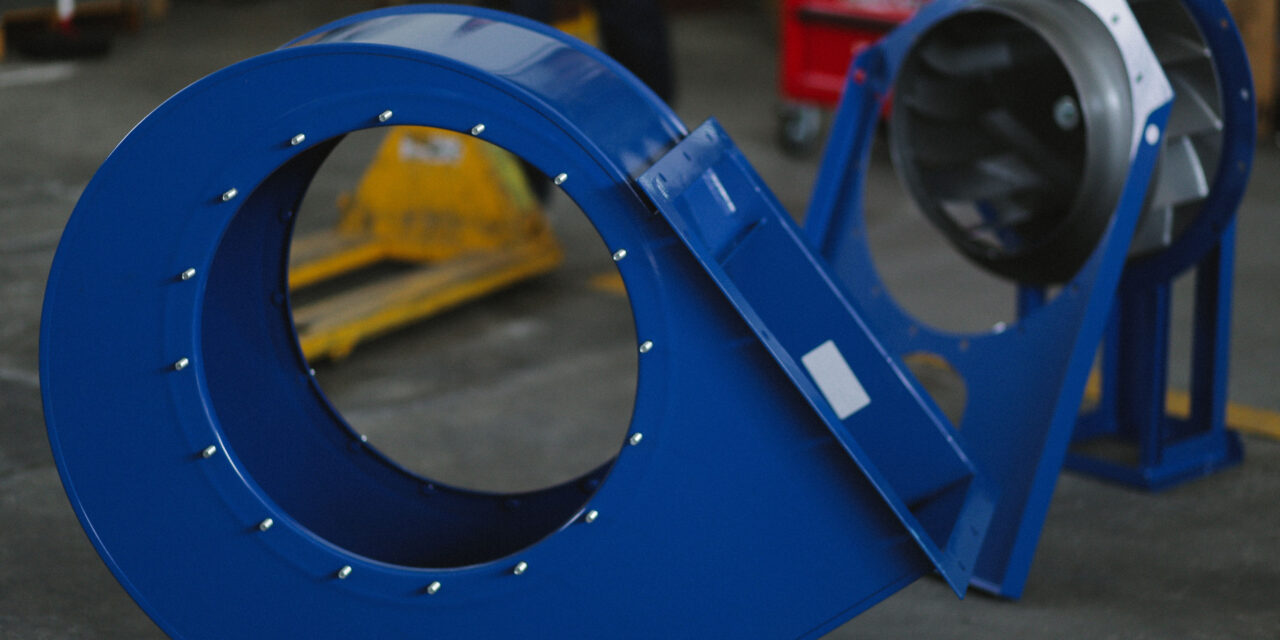

In industrial environments, exhaust and ventilation are crucial for removing dust, fumes, and harmful vapors, protecting both workers and the surrounding environment. Electric motors power fans and filtration systems that ensure constant air exchange and compliance with air quality regulations. Without an efficient motor, these systems would not be able to operate properly, leading to health and environmental risks.

- Emission Control and Air Quality

Electric motors offer great flexibility in terms of speed and airflow regulation, thanks to the use of inverters and advanced control systems. This allows exhaust and ventilation systems to be adapted to the specific needs of the production process, optimizing energy consumption and improving overall system efficiency.

- Environmental Sustainability

With the increasing focus on reducing environmental impact, electric motors represent an important eco-friendly choice. They produce no direct emissions during operation and, when powered by renewable energy sources, further contribute to the decarbonization of industrial processes. Additionally, many electric motors are designed to be recyclable, reducing waste at the end of their lifecycle.

- Compliance with Regulations

The use of efficient and high-performance electric motors is often a requirement to comply with local and international regulations regarding workplace safety, energy efficiency, and environmental protection. Companies that invest in advanced technologies can avoid penalties and enhance their reputation in the market.

Our electric motors WEG meet the highest quality standards, ensuring optimal performance, safety, and environmental compliance. They contribute to a more sustainable future while improving operational efficiency for businesses. We understand that continuous innovation in this sector promises further advancements, making our electric motors increasingly efficient and suited to the needs of modern industry.